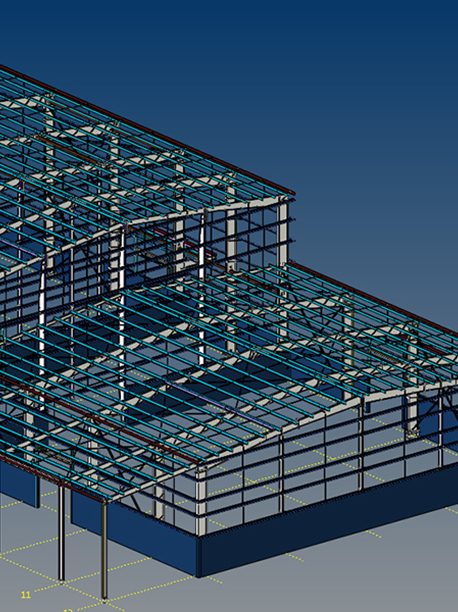

Our huge Infrastructure and Resources at our Savli, Vadodara (Gujarat) plant.

Land Area is 85,000 Sq.M. that is approx. more than 21 Acres and for PEB division, the office building of 600 Sq.M. And Factory Building is of 9,000 Sq.M. contributes to India and International infrastructural growth.

Manufacturing capacity at our Vadodara plant for Primary Structural is 12,000 MT, Secondary Structural 6,000 MT, and Sheeting Material 6,000 MT per Annum. So Total, 25,000 MT per annum to cater India and Export Market.

Men and Machines create wonders wherever we construct buildings. Have a look at a few major types of equipment from the best of the best manufacturers installed at Sankalp.